MTW EUROPEAN TRAPEZIUM MILL

Type:Mineral Ore Powder Making

Input size:33-40 mm

Processed Materials:Limestone, calcite, barite, dolomite, potassium feldspar, bentonite, medical stone, rock phosphate, manganese ore, iron ore, quartz, active carbon, carbon black, ceramic, coal, etc..

Applications:Cement, coal , power plant desulfurization, metallurgy, chemical industry, non-metallic mineral, construction material, ceramics.

Quantities can be customized

The MTW European Trapezium Mill is mainly applicable to grinding process of mineral materials in metallurgy, building material, chemical and mine industries, etc. It can process the non-flammable and non-explosive mineral materials of hardness less than 9 on Moh’s scale, and the humidity less than 6%, including quartz, feldspar, calcite, talcum, barites, fluorite, tombarthite, marble, ceramic, bauxite, manganese ore, iron ore, copper ore, phosphate ore, iron oxide red, zircon sand, mineral waste residue, water granulated slag, cement clinker, active carbon, dolomite, granite, granat, iron oxide yellow, chemical fertilizer, compound fertilizer, flyash, soft coal, coking coal, lignitous coal, magnesite, chromium oxide green, gold ore, red mud, clay, kaolin, coke, coal gangue, porcelain clay, kyanite, fluorspar, bentonite, medical stone, rhyolite, diabase, pyrophyllite, shale, red sandstone, stromatolite, basalt, gypsum, graphite, carborundum, thermal insulation material, etc..

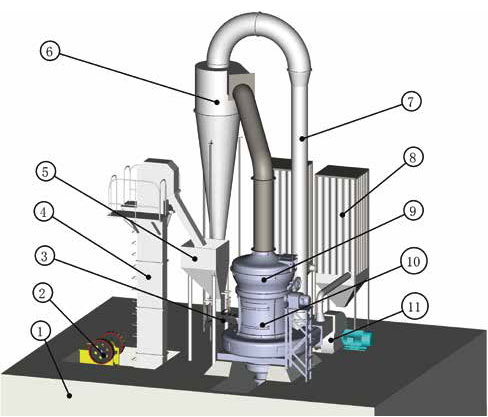

6. Whirlwind powder collector 7. Pipeline 8. Bag-type dust collector 9. Classifier 10. Main unit 11. Fan

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.

Contact us now if you have any question about our company and products. Any of your inquiry and suggestion will be highly appreciated. We will keep your information completely private.

info@cnyhzg.com +86-371-86688302 yuhongmachine

English

English

中文

中文