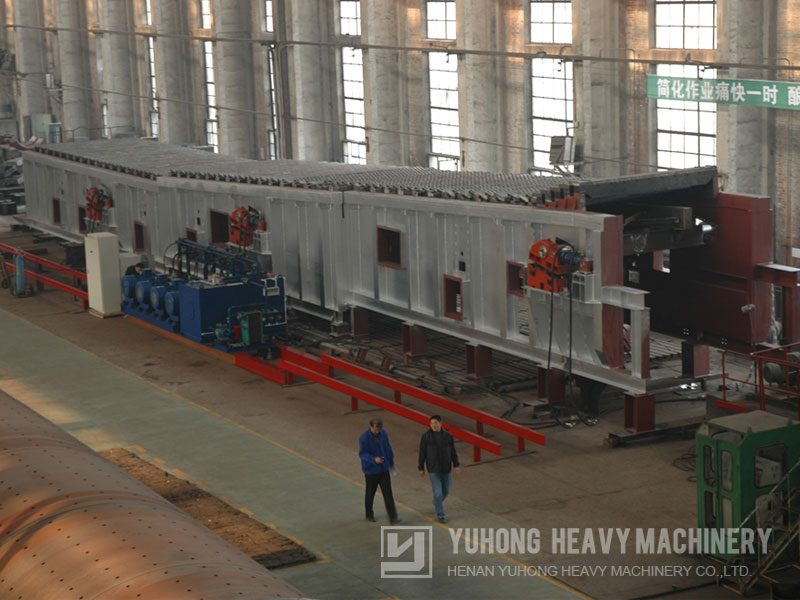

GRATE COOLER

Processing Material:Cement clinker; organic fertilizer, fertilizer, etc.

Application:building materials industry, cement industry, metallurgy industry, chemical industry, etc.

Quantities can be customized

Horizontal grate cooler is an important host device of clinker burning system in cement plant. its main function is to cool and convey the clinker; meanwhile providing hot air for the kiln and precalciner, is the main equipment of heat recovery in firing system.

The traditional grate cooler includes three kind coolers of rotary type, vibrating type and push-type, because the first two type have been eliminated, pushing grate cooler has become the main cement clinker cooler cooling type used in cement kiln which is with precalcining. Our HCFC horizontal grate cooler is a kind of new energy-saving machinery for clinker, and the internationally advanced flow control technology has been employed in this machine. Based on the advanced thermal process, it has been improved greatly, and when compared with other grate coolers, its productivity is 20% higher and its heat consumption more than 10% lower.

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.

Contact us now if you have any question about our company and products. Any of your inquiry and suggestion will be highly appreciated. We will keep your information completely private.

info@cnyhzg.com +86-371-86688302 yuhongmachine

English

English

中文

中文